Technology and Innovation

Jedro Lithium leverages proven technologies and best practices from leading enterprises to produce high-quality, battery-grade Lithium Hydroxide. By adopting established and reliable methods, we ensure efficiency, consistency, and compliance with the highest industry standards, supporting the growing demand for lithium-ion battery materials in the EV sector.

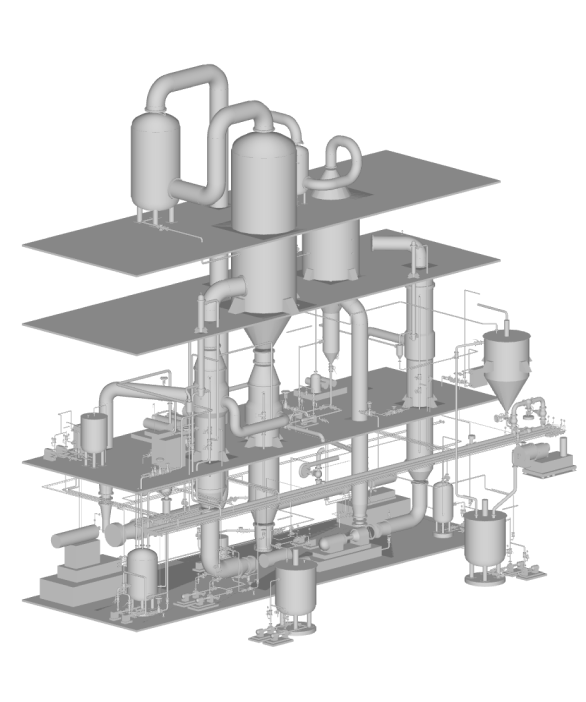

Production Overview

Eco Technologies

We use MVR to evaporate solutions. MVR is short for Steam Mechanical Recompression Technology.

MVR is an ecological energy-saving technology:

- the energy of its own secondary steam is reused, which reduces the need for external energy;

- the evaporation process occurs with full use of the latent heat of steam;

- fresh steam is required in small quantities — only to initiate the evaporation process;

- the entire MVR evaporation system is controlled by a PLC, which minimizes energy consumption to maintain thermal balance;

- the system operates in a closed cycle, ensuring a minimum amount of CO2 emissions into the atmosphere.

A solar panel system will be used to supply energy to the office building and some other consumers.

Jedro Lithium combines proven industrial methods with advanced eco-technologies to create battery-grade Lithium Hydroxide while minimizing our environmental impact. Our cutting-edge processes are designed to significantly reduce carbon emissions. This approach aligns with our commitment to sustainability and supports Europe’s transition to a cleaner, greener future.